High Precision Microengineered StencilsA pioneering stencil solution to meet the challenges of next generation printing The MicroStencil fabrication process represents a breakthrough in the critical field of stencil technologies, delivering exceptional and repeatable precision for a diverse range of demanding applications. Founded on a novel MEMS-based manufacturing process, high accuracy microengineered stencils are capable of achieving the ultra-fine geometries now standard in many of today’s interconnection technologies. This stencil technology overcomes the limitations of conventional stencil manufacturing technologies to meet every ultra-fine pitch printing requirement. The products superior print performance means that the technology is ideally suited to a range of demanding manufacturing applications including:

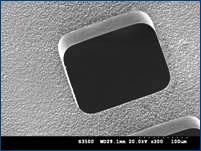

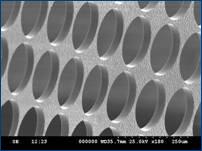

These stencils are commonly used for creating the interconnects in wafer level and flip chip packaging, BGAs, direct chip attach and other fine pitch components such as 01005. Facilitating apertures as small as 25µm on 50µm pitch, microengineered stencils offer MicroStencil customers exceptionally smooth sidewalls for highly efficient paste transfer. As a result the stencils yield excellent print definition and deposit coplanarity. In addition the product has a major advantage that works extremely effectively with underside stencil cleaning systems. Our stencils can smoothly fit into most screen printing machines worldwide.

Product Benefits

In addition the Platinum stencil technology is now offered by DEK in the patented VectorGuard® stencil system. Vector Guard is a frameless mounting system for stencils which delivers enhanced storage convenience, improved stencil dimensional tolerances and breakthrough ease-of-use. For stencil enquires please contact: sales@microstencil.com |