Electroformed components

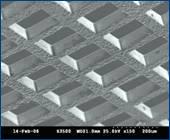

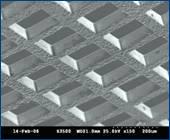

The MicroStencil fabrication process can generate fine feature patterns on electroformed sheets down to 25 microns on foils thinner than 25 microns. Building on its novel fabrication technology originally developed for the production of precision electroformed stencils this process has now been adapted for a number of different applications including:

- Meshes

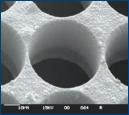

- Sieves

- Filter membranes

- evaporation masks

- optical encoder discs

- orifices for dispensing and jetting applications

- vacuum templates for ball drop applications

- shaver foils

100µm diameter circular apertures 100µm wide square apertures 40µm wide square apertures

Product Specifications

- Available thickness → 20µm to 300 µm at 0.5 µm increments

- Aperture capability → 25µm

- Aperture size tolerance:

- < 3 µm for 50 µm thick foils

- 4 µm for 50 – 100 µm thick foils

- 6 µm for 100 – 200 µm thick foils

- 8 µm for 200 – 230 µm thick foils

- Excellent thickness uniformity across design area +/- 5%

- Minimum pitch → 50µm

Product Benefits

- High accuracy tolerances across the design area

- Ultra-smooth sidewalls

- Low internal stress of plated products

- Different options on stencil hardness and surface roughness available

- Products specifically designed to meet almost any customer requirement

- double or triple build-up layers possible

For enquires please contact: sales@microstencil.com

Back to products page